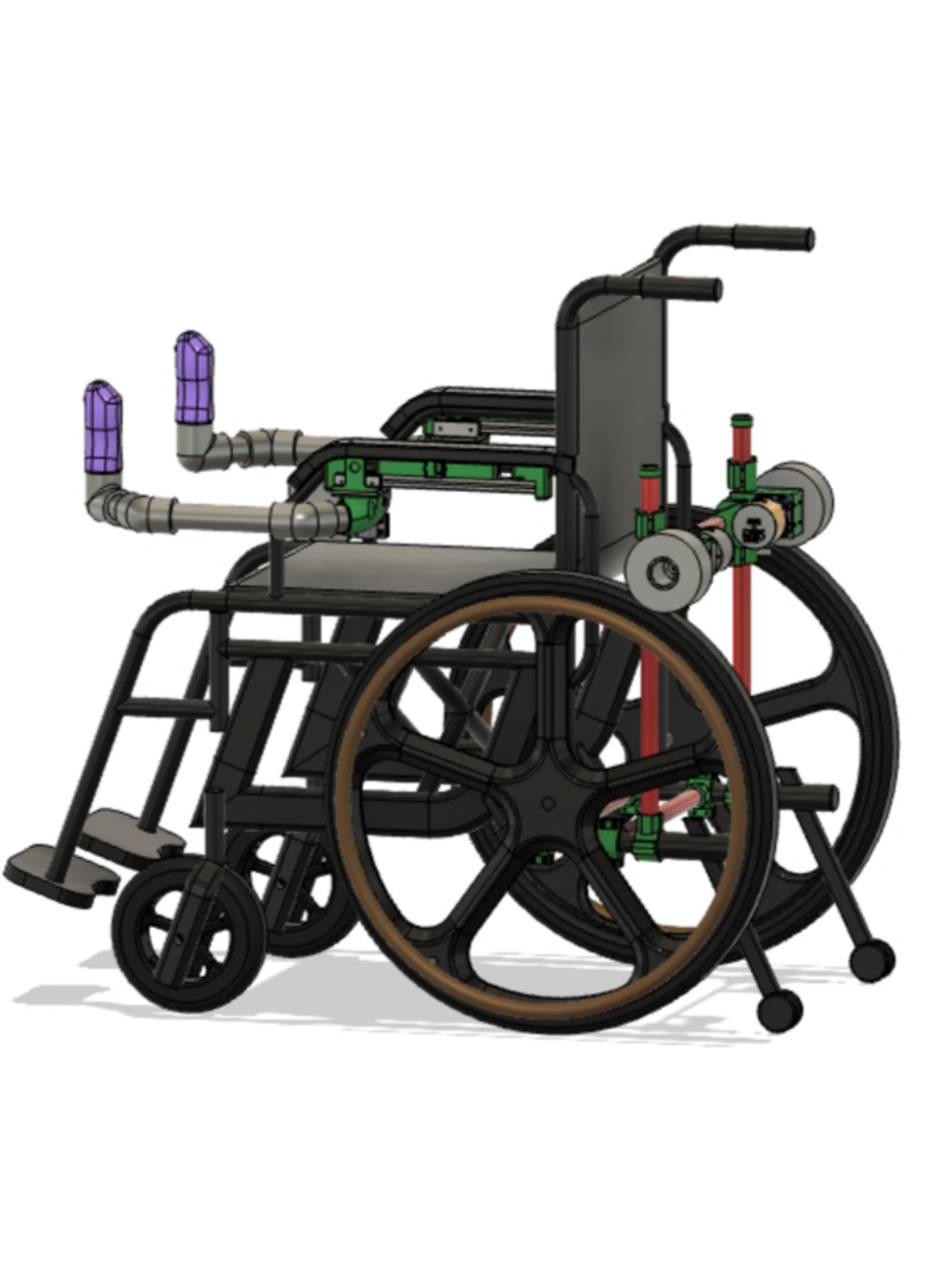

Friction-Drive Power-Assist for Manual Wheelchairs

2-minute full case study (the scroll-through / deep dive)

Context & users

Many manual wheelchair users could benefit from intermittent power assist, but most kits are expensive, heavy, or require permanent frame changes. Goal: a low-cost, removable, motorized friction-assist that keeps manual control intuitive.

Requirements / constraints

No frame modification; compact add-on

Predictable, safe behavior; safety interlock (e-stop), clear states, no creep

Performance: works on flat and mild inclines; roadmap for weather/debris tolerance

Build envelope: complete within an eight-week semester and a limited budget

Solution architecture

Drive: motorized friction roller on the rear tire with 6.25:1 gearbox and NEO brushless motor (sized from load cases)

Structure: modular, serviceable brackets (printed + machined) sized for stiffness and repeatability

Engagement: linear-rail mechanism with momentary push control to apply/remove assist consistently

Electronics: enclosed controller and wiring harness designed for field access and quick swaps

Engineering highlights

Sizing & calcs: torque/speed trade-offs (target ≈ 137 W, 28 N·m stall); contact pressure for traction without tire wear

FEA: bracket stiffness and housing stress; geometry tuned to avoid slip/chatter under load

Controls: simple state diagram (idle → assist → e-stop); current limit and safe default behaviors

Build & test

Bench: printed fixtures for rapid iteration; roller load, current draw, and basic thermal rise tests

Field: measured speed on flat/mild inclines; logged current and temperatures; tuned roller compound and preload

Tuning goal: preserve fine manual control while providing noticeable powered assist

Results

Assist: walking-speed assist on flat; usable assist on mild inclines

Handover: smooth handover between powered and manual modes

Safety: integrated e-stop; no failures during multi-session, multi-km tests

What I’d ship next

Weather sealing and debris guards on the roller/mechanism

Manufacturable enclosure and harness; standardized hardware

Endurance and wear testing; long-duration thermal and duty-cycle characterization

Control refinements (engagement feel, current ramp, battery management)

Gallery

-

Friction-drive assist prototype; bolt-on module—no frame modifications.

-

System layout: twin rollers drive rear tire; handle inputs route to compact controller.

-

Drive module: low-profile roller, printed brackets, and quick-service mounts.

-

Power path used for sizing: motor → gearbox → roller → wheel (sanitized).

-

Serviceable electronics enclosure and harnessing; quick-disconnects for maintenance.

-

-

-

-