Shutter Timing Test Rig (DOE & Automation)

2-minute full case study (the scroll-through / deep dive)

Context & goals

Ensure the shutter meets timing spec under heat and duty-cycle variation while reducing manual effort and producing traceable, repeatable evidence for engineering sign-off.

Requirements / constraints

Target timing ± tolerance; jitter below threshold

Thermal range covering expected field conditions

Repeatable fixture; no changes to the device under test (DUT)

Automated logging with CSV export and plotted summaries

Clear pass/fail criteria and full test-matrix coverage

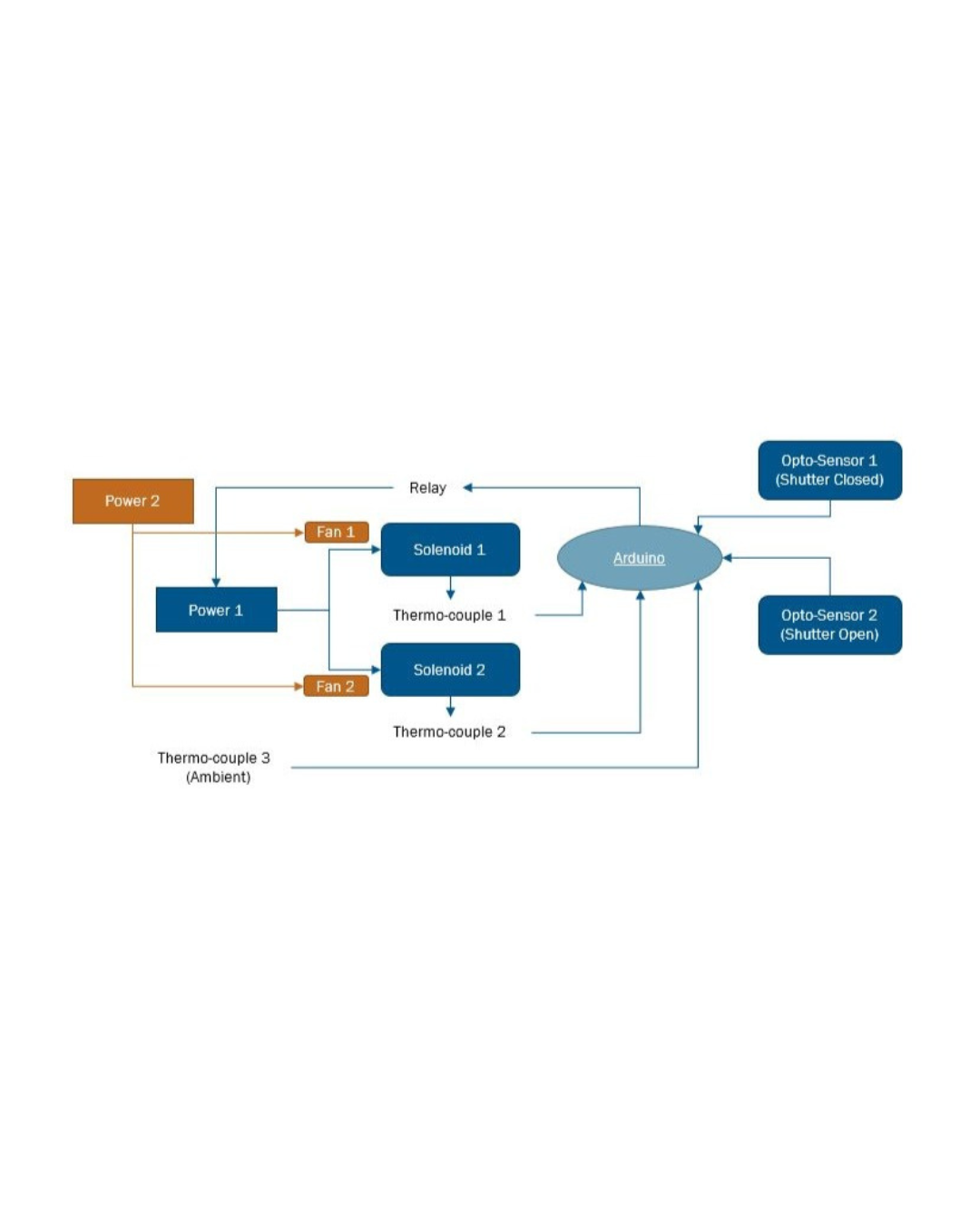

Test architecture (sanitized)

Instrumented rig: shutter + optical sensor → microcontroller (Arduino (C/C++)) with reference timing

Thermal loading: controlled heat/soak with temperature logging

Light control: shroud to block ambient light; fixed distance and angle

Fixture: rigid mount, tool-less swaps, indexing for consistent alignment

DOE plan

Factors: temperature, duty cycle, pulse width (optional: supply voltage)

Responses: actuation latency, jitter, missed events

Design: randomized order, N replicates per cell, guard runs for warm-up

Criteria: timing ≤ spec; jitter ≤ limit; 0 missed events

Automation & analysis

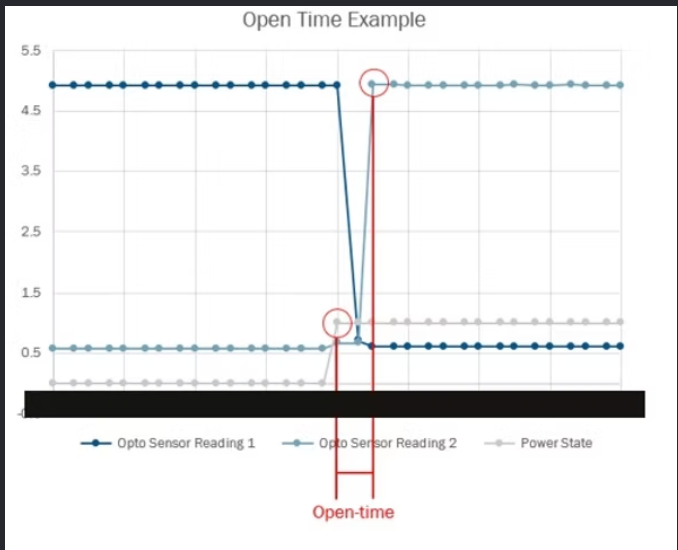

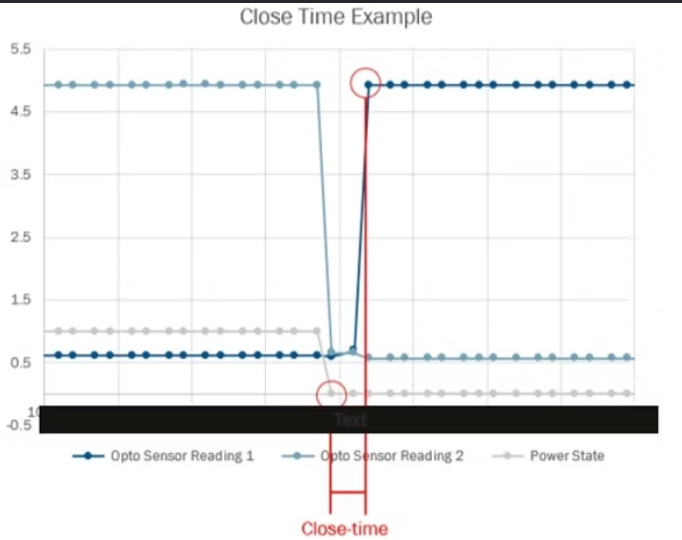

Acquisition: Arduino timestamps with factor levels and run IDs written to CSV

Pipeline (MATLAB): ingest → QC flags → histograms/CDFs → summary tables

Plots: latency vs. temperature; jitter distribution; control charts by factor

Results

Timing met spec across the tested thermal range; jitter below limit in all cells

Identified a duty setting that minimizes thermal drift

Generated a one-click report (plots, tables, pass/fail summary)

What I’d improve next

Add an environmental chamber with controlled ramps and humidity

Run long-duration endurance with vibration overlay

Enclose the rig; add a self-check routine and a calibration artifact

Integrate into CI for nightly regression with alerts

Gallery

-

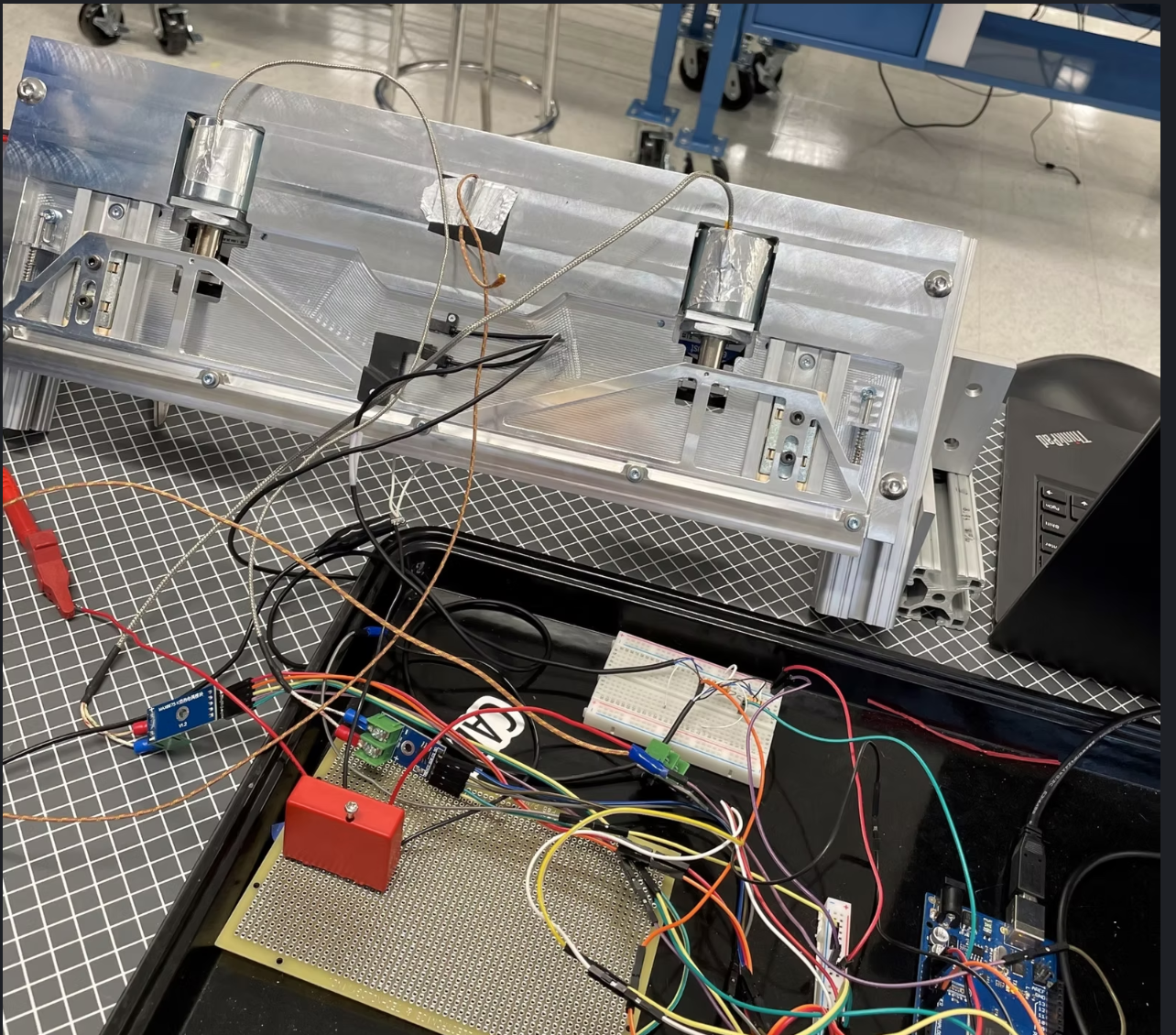

Modular bench rig with fixture, sensors, and data logging (from original DOE setup).

-

Automated cycling with MATLAB data filtering to identify key variables.

-

Shutter mechanism states used for timing definitions (open)

-

Timing definitions used for acceptance: close-time (sanitized).

-

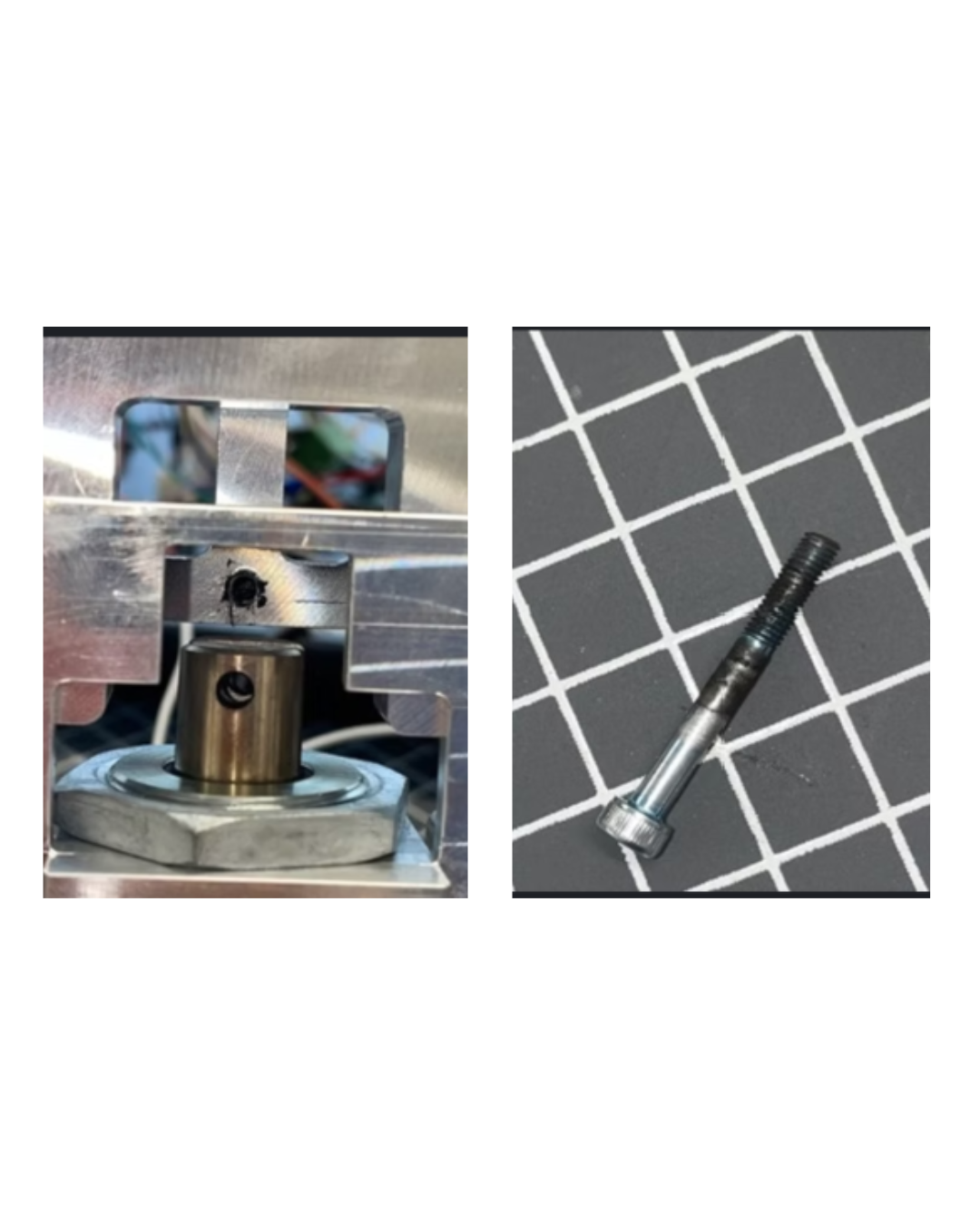

Reliability finding and corrective action: shoulder-bolt fatigue → larger shoulder bolt with pin rather than thread (no further failures observed).

-

-

-

-